Texas Instrument Battery Management System Can Raise The Range of EVs by 20%

TI claims that the new battery management system can raise the range of electric cars by 20%. AT CES 2023, Texas Instruments announced its latest battery cell and battery pack management tools. Here we are going to know how BMS technology can increase the EV's range. Below are the technical reasons for wiring diagrams of the intricacies of transistor design.

Actually, it is possible because of the new TI components which are able to understand better what is happening inside the battery pack using that information to more accurately predict its performance and range. The new battery controls BQ79718-Q1 (battery cell monitor), and BQ79731-Q1 (battery pack monitor). These 2 are helpful to maintain the best level of accuracy and precision in finding the current, battery voltage, and temperature to know the true range of a vehicle.

Sam Wong said that "automakers aim to get the most range possible out of their EVs, and accurate state of charge estimations are vital to achieving this. The general manager of BMS said that "our new devices bring substantially higher precision to voltage and current measurement, giving automakers confidence to accurately measure an EV’s true range".

Do Check

- Affordable EV Cars

- US Postal Service Hopes Electric Delivery Vehicles by 2026

- New Electric Vehicles Models to Look Forward to in Australia in 2023

Critical Battery Management System Functions

Electric vehicles are becoming popular day by day, and the challenge for automakers is to reflect a true electric car range while making the vehicle more affordable. It relates to making battery packs that lower costs with increased energy densities. Every single watt hour stored and retrieved from the battery is crucial in increasing the driving range, the company says.

The BQ79718-Q1 allows automakers to maximize true electric car driving range with high-performance battery cell voltage measurements down to 1 mV of accuracy. The BQ79731-Q1 allows the battery pack measurement current down to 0.05% of accuracy. It shows that it is the best way to measure the state of charge, and state of health at the individual cell and pack levels accurately. It allows the drivers to have clear information about the true range of EVs at any time.

Best in industry voltage and current synchronization enables instant monitoring of battery pack power, which gives a real-time snapshot of battery health. This level of synchronization allows electrochemical impedance spectroscopy, which gives an important insight into the cell core temperature, battery ageing, and state of charge of the battery.

The BQ79718-Q1 battery cell monitoring integrated circuit attains an unprecedented ASIL accuracy, giving automakers the ability to charge and discharge an EV's battery pack beyond any cell monitor previously on the market.

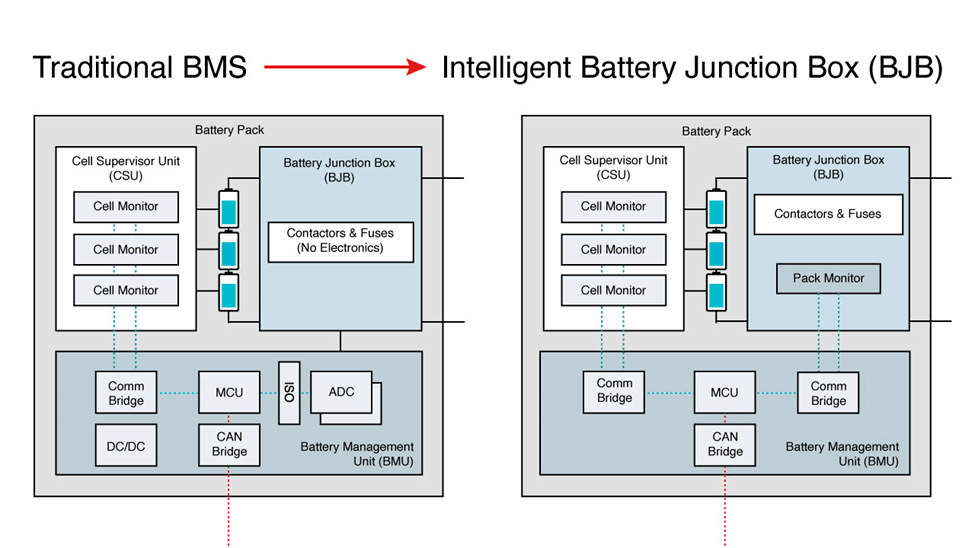

The above image denotes a typical BMS architecture having a battery management unit, a cell supervisor unit, and a battery junction box. A battery management unit has a microcontroller which manages all of the functions within the battery pack. The traditional BJB is a switch box with power contactors that connects the entire battery pack to the load inverter, motor, or battery charger.

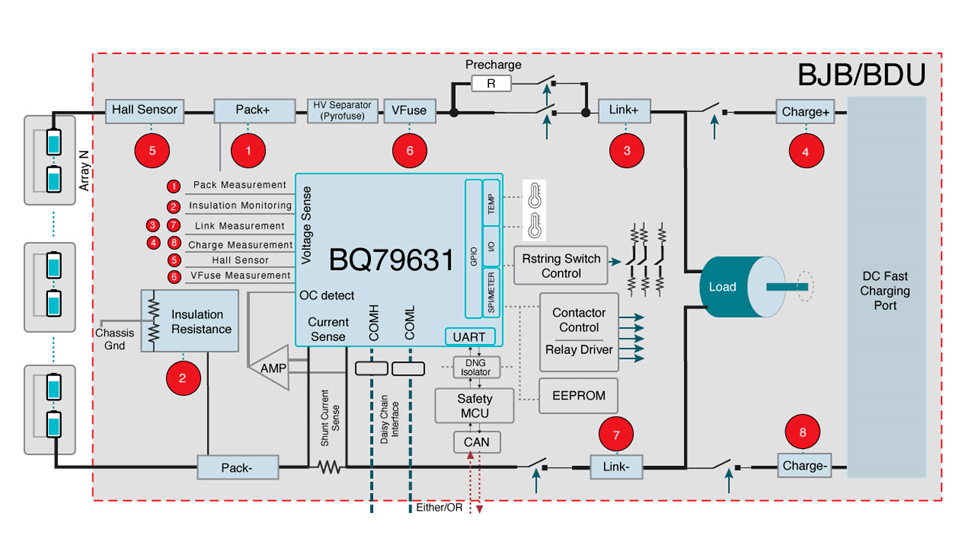

The above figure shows the different high voltages, currents, and temperatures that the pack monitor measures inside a BJB enabled by the BQ79731-Q1 battery pack monitor.

Voltage:

The high voltage is measured with divided-down resistor strings.

Temperature:

The temperature measurement monitors the temperature of the shunt resistor so that the MCU can apply for compensation, and the temperature of the contractors to make sure that they are not stressed beyond the normal operating conditions.

Current:

The current measurements are based on either a shunt resistor or a hall effect sensor.

The primary function of a battery management system is to monitor cell voltages, pack voltages, and pack current. Because of the high voltage design of the BMS, the insulation resistance measurement that lies between the high voltage domain and low voltage domain is required to catch defects in the battery structure and protect against hazardous conditions.